Tire Disposal,Tyre Rececycling Machine With Microwave Technology

This project has been suspended.

Tyre Rececycling Machine-Microwave and cyclic pyrolysis gas heat the tire together, microwave efficiency improved greatly, uniform heating through complementary principle. Middle-low temperature, stable and controllable oil yield, greatly improve the quality of carbon black, produced continuously.

A 100kg/h experimental production line has been built. Not only has it been operated for a long time, but also a large amount of carbon black has been prepared for sampling and inspecting.

Waste Tire

Proportion of pyrolysis products (different material has different data)

◆ Carbon black: 35%

Carbon black from pyrolysis

Compared with the traditional pyrolysis carbon black, the quality of the finished product is greatly improved. The refined product can be directly used in rubber products and has good reinforcing properties. Over the feathure of the carbon black from ours is near N660.

Report for Carbon Black from Waste Tire Disposal

| Item | Test items | Measured value | Item | Test items | Measured value |

| 1 | Iodine absorption g/kg | 170 | 10 | 300% fixed stress

(Difference from IRC) MPa

| -3.4 |

| 2 | Oil absorption value (D method-DBP) 10-5m3/kg | 86 | 11 | Tensile Strength

(Difference from IRC) MPa

| -1.2 |

| 3 | CTAB Adsorption surface area 103m2/kg | 62 | 12 | Elongation at break

(Difference from IRC) %

| +19 |

| 4 | Total surface area 103m2/kg | 66 | 13 | Tear strength kN/m | 47.2 |

| 5 | External surface area 103m2/kg | 48 | 14 | Shore hardness Shore A | 64 |

| 6 | Heating reduction % | 1.5 | 15 | Resilience % | 58 |

| 7 | Ash ( 825 ℃) % | 11.1 | 16 | Abrasion volume cm3 | 0.5 |

| 8 | 45 μm Sieve residue mg/kg | 254 | 17 | Scorching time s | 47 |

| 9 | PH value | 8.7 | | | |

◆ Pyrolysis oil: 35%–40%

Pyrolysis Oil

Similar to light fuel, it can be drrectly used for fuel combustion or mixed with petroleum-extracted fuel oil. It can also be used as rubber processing softener.

◆ Pyrolysis gas: 8—15%

Mainly composed of hydrogen and methane, can be used as fuel, in this system as the energy source of circulating cracking gas.

◆ Steel wire: 10%

Stainless wire

Recyclable as scrap metal.

Basic Structure of the tire disposal machine:

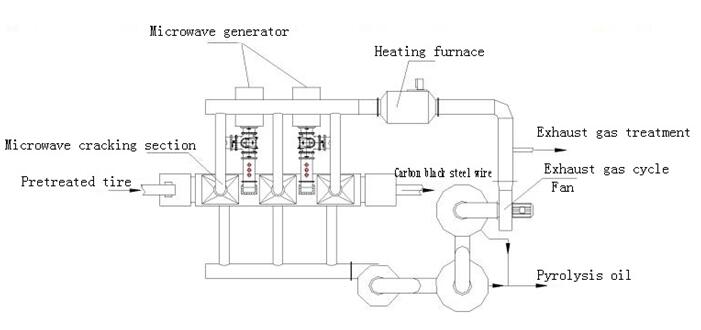

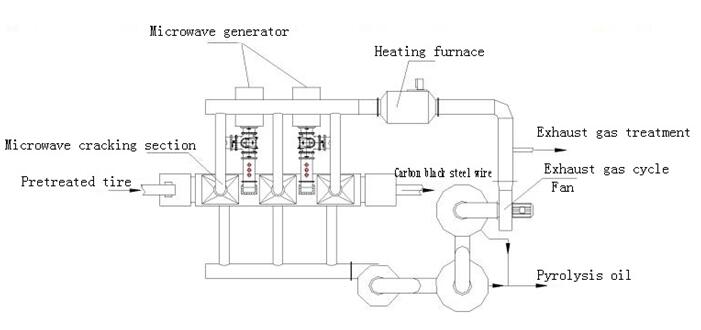

The equipment comprises five parts: a raw material pretreatment section, a microwave cracking section, an exhaust gas circulation section, an exhaust gas treatment section and a discharge section.

The pretreated tire block is conveyed to the microwave cracking section by automatic feeding. Under microwave volume heating and external exhaust gas heating, the tire block quickly passes through the cracking section under the conveyor belt, which enables rapid cracking and product separation of the tire block. The microwave cracking section is equipped with a 100kw microwave source, which can provide sufficient microwave intensity to achieve industrialized single-machine large-scale rapid cracking. The oil and gas produced by the cracking is condensed in the tail gas circulation section and turned into cracking oil, which then passes through the fan and enters the tail gas treatment section. The cracked carbon black and steel wire are transported to the discharge section by the conveyor belt, and the carbon black and the steel wire are sorted by the separation operation device, thereby completing the whole process of tire cracking. (as picture shown)

Background Of The Tech Of Microwave To Make The Tyre Disposal

◆ About 2 billion tires are scrapped yearly in the world, and China accounts for 0.3—0.4 billion (1—2 million tons)

◆ Molecules of rubber are extremely stable, degradation for hundreds of years, environment pollution.

Current main process methods

1. Refurbish, affected by the national standard “technical conditions for the safety of motor vehicles in operation” (GB7258), production has been reduced.

2. reclaimed rubber, low production on technology, poor product quality, low economic benefit, high environmental cost.

3. Pyrolysis, rubber tire has high calorific value. For pyrolysis oil has been recognized by the market, however:

◆ the price of crude oil impact on economic benefits greatly.

◆with heat transfer slowly, non uniformly, the traditional technology complete the pyrolysis (up to 8 hours), can hardly realize continuous production.

◆ moreover, the carbon black produced is valueless, which environmental costs are unbearable.

Related Items