MPCVD Machine,6KW MPCVD Reactor,MPCVD,Lab Grown Diamond

6kW MPCVD machine is particularly suitable for single crystal and polycrystalline diamond film CVD process, polycrystalline diamond (Polycrystalline Diamond) film chemical vapor deposition (CVD) ), surface treatment and modification of materials, high-quality diamond growth and low-temperature oxide growth and other applications.

♣Component

MPCVD machine includes control unit (PLC + touch screen, etc.), microwave unit (2450MHZ 6KW solid-state microwave generator, microwave transmission system, etc.), water cooling unit, vacuum unit (vacuum pump, vacuum measuring instrument) ,and others.

♣Working Processing

The mpcvd machine controls the flow of each gas path and the cavity pressure, and introduces the reactant gas source (CH4, H2, Ar, O2, N2, etc.) into the cavity and controls it under a certain pressure.After the airflow is stabilized, microwaves are generated by the 6kw solid state microwave generator, and then the microwaves are introduced into the cavity by the waveguide.

Under the action of the microwave field, the reaction gas becomes a plasma state, forming a plasma ball suspended above the diamond substrate, and the high temperature of the plasma is used to heat the substrate to a certain temperature.The excess heat generated in the cavity is conducted away by the water cooling unit.

In the single crystal diamond (MPCVD) growth process, we ensure the optimal growth conditions by adjusting the power size, gas source composition and cavity pressure and other conditions. In addition, because the plasma ball has no contact with the cavity wall, this ensures that no impurities are mixed in the diamond during the growth process and improves the quality of the diamond.

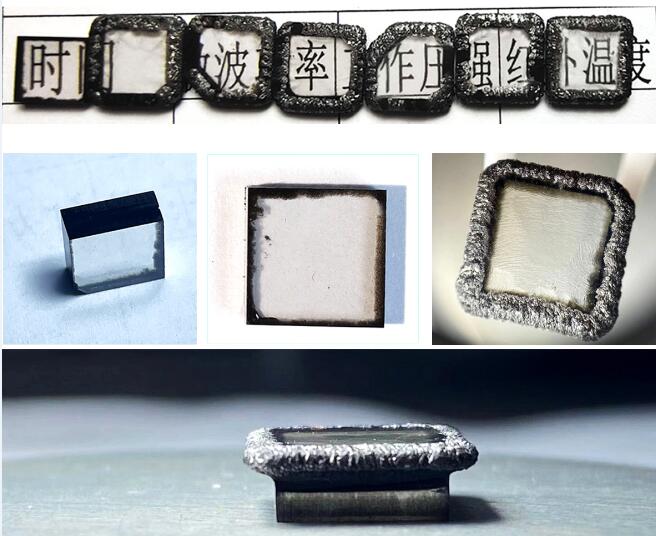

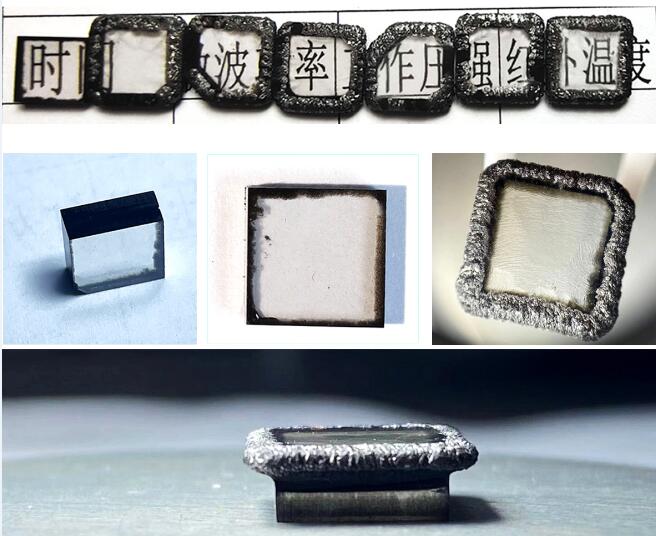

Lab Grown Diamonds

Parameters of the MPCVD is as below:

| Type | HMPS-2060SP |

| Total power supply | 380VAC±5%/50Hz, three-phase four-wire, separate ground wire, 12kW |

| Equipment dimensions | 1.95 (L) x 0.9 (W) x 1.85 (H) m |

| Item | Data |

| Microwave frequency | 2450MHz |

| Solid-state microwave output power | 0.1~6kw continuously adjustable |

| Microwave power stability | better than ±1% (at rated power level) |

| Micro-waviness | better than 1% |

| Control method | PLC control, 12-inch touch screen operation |

| Output waveguide interface | BJ-26, 22 with FD-26, 22 standard flange |

| Microwave vacuum discharge chamber | Φ200 x 300(H)TM mode |

| The plasma discharge area | More than Φ50mm in diameter;

Stable discharge without shifting |

| Substrate temperature measurement | Infrared temperature measurement range 300~1400℃ (monochrome) |

| Substrate table device | Diameter of substrate table Φ60 mm;

Water cooling |

| Effective adjustment amount of base station and cavity plate servo motor: 0~20 mm | 0~20 mm |

| Working temperature | 600~1200℃ (infrared temperature measurement);

Control accuracy ±5℃ |

| Working pressure | 10torr~200torr, control accuracy 0.1torr |

| Continuous stable working time under normal conditions | >48h |

Related Items